0086-519-82305398

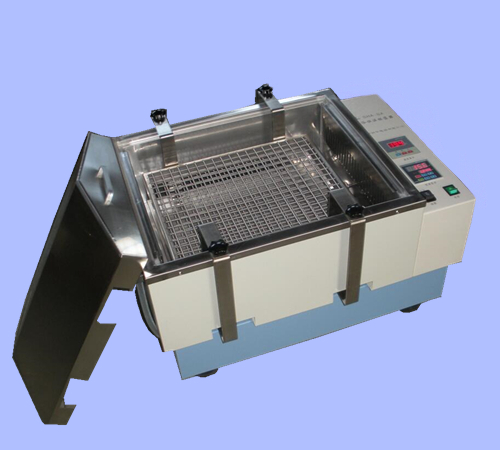

Overview:1、 Water bath thermostatic oscillator (also known as water bath shaker) features: Constant speed water bath constant temperature oscillator: it is a kind of biochemical instrument with temperature controlled constant temperature water bath and oscill…

Consulting1、 Water bath thermostatic oscillator (also known as water bath shaker) features:

Constant speed water bath constant temperature oscillator: it is a kind of biochemical instrument with temperature controlled constant temperature water bath and oscillator. It is an indispensable laboratory equipment for precise cultivation and preparation in scientific research, education and production departments such as plants, biology, microorganism, genetics, virus, environmental protection, medicine, etc. Its main features are: 1. Accurate temperature control and digital display. Speed controllable, constant speed constant, digital timing. ② There are small waves in oscillation, but no splash. ③ With mechanical timing. ④ The universal spring bottle rack is especially suitable for the cultivation and preparation of biological samples for various comparative tests. ⑤ Stepless speed regulation, speed digital display, stable operation, simple and safe operation. ⑥ The inner cavity is made of stainless steel and has good corrosion resistance.

2、 Parameters of thermostatic oscillator: all materials of inner liner are 304 (8ni) stainless steel

|

model

|

SHA-CA |

|

|

|

|

Speed range |

start~300rpm Constant speed setting |

|||

|

Temperature range |

room temperature~100℃ |

|||

|

Temp Accuracy |

±0.5℃ |

|||

|

Volatility |

±0.1℃ |

|||

|

Amplitude |

20mm |

|||

|

Oscillation mode |

|

Horizontal reciprocating |

|

|

|

heating power |

1800W |

|||

|

Tank size |

490×390×170 |

|||

|

Intelligent timing |

0~9999min(Or normally open) |

|||

|

Power Supply |

AC220v 50Hz |

|||

|

Overall power |

2000W |

|||

|

Size of rocker plate |

400x300mm |

|||

|

Instrument dimensions |

710x510x500mm |

|||

|

Speed measurement range |

Start up - 300r / min [subject to start number] |

|||

3: Operating instructions of constant temperature and constant speed oscillator:

1. The service life of the instrument can be prolonged if it is used at medium speed within the speed range.

2. The instrument should be placed on a firm working table, the environment should be kept clean and tidy, ventilated and dry, and convenient for water supply and drainage.

3. Before using the instrument, put the speed control knob at the minimum position and turn off the "oscillation switch".

4. The following points should be paid attention to when filling the culture test bottle: ① evenly distributed; ② the liquid volume should not be too small to prevent the test bottle from floating; ③ seal the mouth of the test bottle to prevent the condensed water drops from dropping into the test bottle.

5. Inject the tap water into the water tank, and the water level should be slightly higher than the inner liquid level of the culture bottle.

6. Turn on the external power supply, set the power switch to the "on" position, and the indicator light will be on.

7. Select constant temperature:

a. Set temperature: press set key to set or view the temperature set point. Press the set key once, the nixie tube character starts to flash, indicating that the instrument enters the setting state. Press the △ key to increase the setting value and press the ▽ key to decrease the setting value. If you press the △ or ▽ key for a long time, the data will change rapidly. Press the set key again, and the instrument will return to normal working state. After the temperature is set, the start heating indicator will be on.

b. Advance setting: press set key for 3 seconds, and the instrument will enter the inner parameter setting state. The first parameter that appears and flashes is In order to reduce the temperature overshoot, the heating will be cut off in advance when the temperature drops below the advance value. The output (relay) will not work within the range of the set value and advance amount, which can reduce the relay action times and prolong the service life of the relay. For example: if the set value is 50.0 ℃ and the advance is 0.5, the relay will release when the instrument control is heated to 49.5 ℃, and the relay will pull in when the temperature drops to 50.0 ℃ - 0.5 ℃ = 49.5 ℃. The larger the advance, the less the relay action times. If the advance is too large, the control accuracy will be reduced. After adjusting the advance parameter, press set key for 3 seconds, and the instrument will return to working state. (Note: the advance setting is specially set to prevent too high temperature shock after heating stop, and it is not necessary to modify it in general).

c. Error correction: when confirming that the value displayed by the instrument is not the correct measurement value, the displayed value can be corrected. Press the set key for 3 seconds to enter the inner menu of the instrument. The first parameter that appears and flashes is E00, which is the advance amount. Press the set key again, and the parameter that appears and flashes is the error correction parameter. This parameter can be modified with △ or ▽ keys. The range of error correction is - 9.9 ℃ to + 9.9 ℃, and then press the set key to exit. The correction value of the instrument is 0.0 when it is delivered from the factory. It is necessary to prevent the instrument with correct display from being corrected to incorrect.

8. Select timing and set the timing knob to "timing" or "normally open".

9. Turn on the "oscillation switch", the indicator light is on, slowly adjust the speed control knob, observe the speed display screen, and increase to the required speed.

10. Before each shutdown, all switches should be set to non working state, and the timer should be set to "zero" to cut off the power supply.

11. It is forbidden to use the heater without water in the water tank. If the instrument is stopped for a long time, the water in the water tank should be drained and dried with a soft cloth.

4、 Maintenance of digital display water bath thermostatic oscillator:

1. Use the instrument correctly and pay attention to the maintenance to make it in good working condition and prolong the service life of the instrument.

2. During the continuous operation of the instrument, regular inspection should be carried out every three months: check whether there are water drops and dirt falling on the motor and control elements; check the water quality and cleanliness of the water tank; check the fuse, control elements and fastening screws.

3. The bearing of the transmission part of the oscillator has been filled with a proper amount of grease before delivery. During the continuous operation of the instrument, the grease should be filled every six months, which accounts for about 1 / 3 of the bearing space.

4. The natural wear of the instrument is normal after long-term use. After using the instrument for one year, our company will continue to provide high-quality service and assist in processing.

Welcome to the official website of Runhua Instruments. We are a professional manufacturer of laboratory instruments. Quality and reputation a…

The water bath constant temperature shaker is a biochemical instrument that combines a temperature controllable constant temperature water ba…

Series of biochemical incubators:Features of 150A biochemical incubator: the biochemical incubator has the function of cooling and heating tw…

High-precision stirring water bath produced by Runhua Instruments:1) The general water bath does not have the circulating stirring function. …

Maintenance and maintenance of electric mixer1. Correct use and attention to the maintenance of the instrument to keep it in good working con…

What work should be done in the use of digital display stainless steel electric heating plate? Digital display stainless steel electric h…