0086-519-82305398

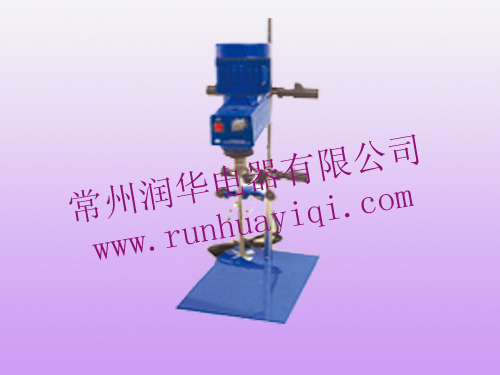

Overview:1、 Overview The cantilever type constant speed powerful electric agitator integrates the advantages of external mixer. It is designed for mixing and mild liquid with low to high viscosity in laboratory. The mixer must be installed on the support and …

Consulting

The machine realizes stepless speed regulation through friction wheel drive system, but the motor always runs at a fixed working point, and the power output speed and torque of the motor reach the optimal value at this point and basically keep constant. The power is transmitted to the stirring shaft through a friction wheel and a central shaft equipped with a pair of plastic couplings. The two gear trains are configured on the same two shafts to form a two speed manual adjustment. If the loss in power transmission is ignored, the power at the end of the mixing shaft is always equal to the output of the motor, and a pair of spiral couplings on the central shaft keep the wear of the friction wheel at a low level. The coupling device automatically adjusts the pressure required on the friction wheel according to the load on the mixing shaft. Low load causes low pressure and high load causes high down pressure.

In the experiment, attention should be paid to the position and capacity of the mixing head, especially the glass container. The mixer must be turned off before shifting, otherwise the reduction gear may be damaged. The machine is equipped with two speeds, I for low speed, II for high speed. The preset position is gear II. When shifting from gear II to gear I, turn the plastic bearing sleeve anticlockwise (looking from top to bottom) to the stop position. Pull down 5.5mm and turn clockwise until the sound of steel ball reset in bearing sleeve is heard. When shifting from gear I to gear II, rotate the bearing sleeve anticlockwise to the stop position, push up 5.5mm, and then rotate clockwise until the sound of steel ball reset is heard.

3、 Cleaning and maintenance

4、 Technical parameters

Motor output power: 200W

Rated power supply: 220-250v

Working state: continuous working for a long time

Maximum torque of mixing shaft: 1850gcm

Speed regulation range: 60-500rpm for stage I

Class II 240-2000 rpm

Maximum mixing capacity (water): 20 liters

Ambient temperature: 5 ∽ 40 ℃

Clamping range of drill chuck: 0.5 ∽ 10mm

Suitable medium viscosity: 0 ∽ 10000mpas

Welcome to the official website of Runhua Instruments. We are a professional manufacturer of laboratory instruments. Quality and reputation a…

The water bath constant temperature shaker is a biochemical instrument that combines a temperature controllable constant temperature water ba…

Series of biochemical incubators:Features of 150A biochemical incubator: the biochemical incubator has the function of cooling and heating tw…

High-precision stirring water bath produced by Runhua Instruments:1) The general water bath does not have the circulating stirring function. …

Maintenance and maintenance of electric mixer1. Correct use and attention to the maintenance of the instrument to keep it in good working con…

What work should be done in the use of digital display stainless steel electric heating plate? Digital display stainless steel electric h…