0086-519-82305398

Overview:Operation manual of independent digital display constant temperature water bath1、 PurposeIndependent constant temperature water bath is widely used for distillation, drying, concentration and impregnation of chemicals or biological products.2、 Of th…

ConsultingOperation manual of independent digital display constant temperature water bath

1、 Purpose

Independent constant temperature water bath is widely used for distillation, drying, concentration and impregnation of chemicals or biological products.

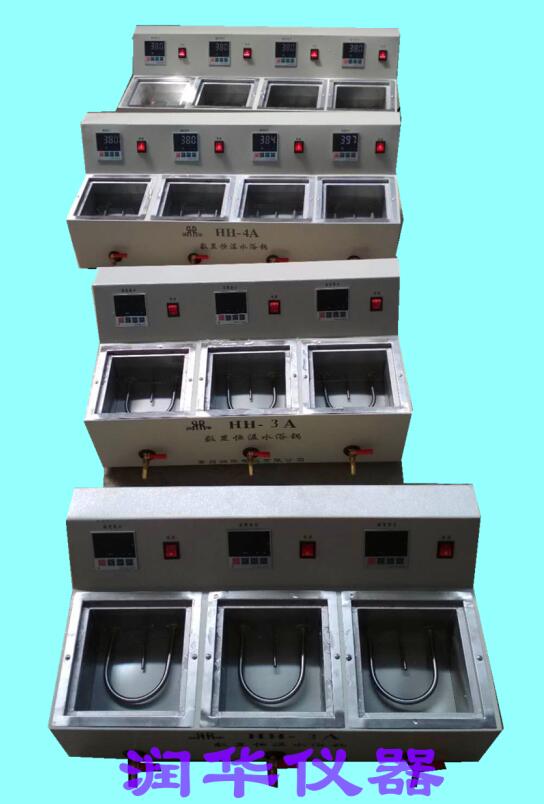

2、 Of the same type [two hole two temperature independent type, three hole three temperature type, four hole four temperature type]

Single row two holes: heating power: 300W x 2 holes temperature control mode: 2 holes x 2 air two temperature

Working size: (160x160x130mm) x2 overall dimension: 400x360x300mm

Single row three hole: heating power: 300wx3 hole temperature control mode: three hole X3 three hole three temperature

Working size: (160x160x130mm) X3 overall dimension: 680x370x320mm

Single case with four holes: heating power: 300wx4 temperature control mode: 4-hole X4 four hole four temperature

Working size: (160x160x130mm) X4 overall dimension: 900x370x320mm

Power supply: 220 V, 50 Hz, temperature control range: independent type, room temperature of each boiler - 100 ℃

Temperature control accuracy: ± 0.5 ℃, fluctuation: ± 0.1 ℃

Instrument model: hh-2a / hh-3a / hh-4a

Series of independent digital display temperature control water bath boiler

3、 Structure

This product is a flume type, with a maximum aperture of 12 cm on the mouth surface and a cover of four circles per hole. The inner pot is made of 304 stainless steel. The shell is made of high-quality thin plate and sprayed with plastic. The electric heating tube is installed in the middle of water, which can heat quickly and save power consumption. It is equipped with a digital constant temperature device. The adjustment range is normal temperature - 100 ° C, and the error is ± 0.5 ° C.

usage

1. When using, water must be added into the pot first, and then the power supply is connected. To set the temperature, press the set key to enter the temperature setting mode to set or view the set value. Press the set key to see the number flashing. In the setting mode, press the up button to increase the setting value and the down button to decrease the setting value. If you keep pressing the button, it will increase or decrease to the value you need. After setting, press the set button again to exit the setting mode and return to the normal working measurement mode.

2. Adjust parameter SC: press the set key for 3 seconds and enter the internal parameter setting adjustment interface. The interface shows that SC is the error calibration value, indicating the error between the measured value and the actual value of the temperature controller. The default value is 0.0. You can press the set key again to display the flashing number to enter the adjustment state (the following parameter setting method is the same), and press the up or down button to adjust the value. (-9.9~9.0)

E: After setting, press the set key to enter the next parameter adjustment. The interface shows that e represents the advance of breakpoint control (only effective when p value is set to 0). The default value is 0.5, and the adjustment method is the same as that of SC.

P: Then press the set key to enter the third parameter. The interface shows that P indicates the setting of P value, and the meaning of P value is roughly the starting control temperature = set value - (10 / P value). If it is set to 50 degrees, when p is 10, it means that 49 degrees begin to control; when p is 4, it means that adjustment begins at 47.5 degrees. If the temperature overshoot is too large, adjust the p value appropriately. If the temperature rises too slowly or the control temperature is not reached, adjust the p value appropriately.

Note: when p value is 0, the breakpoint control mode is entered. That is, the system PID fails. When the temperature is lower than (set value - E value) , it will start heating, otherwise it will stop heating.

c: Then press the set key to enter the setting of the last parameter C. the last parameter is reserved for the system temporarily. Please do not adjust it. The default value is 20.0. After setting all parameters, press set key to return to normal working state. Do not add too much water in the pot, so as to avoid water overflowing out of the boiler when boiling. Pay attention to that the water in the pot can not make the electric heating pipe out of the water surface, so as to avoid burning the electric heating pipe and causing water leakage.

5、 Precautions

(1) In order to ensure safety, please connect the ground wire when using.

(2) Do not add water and dry burn.

(3) When not working, the power should be cut off to prevent accidents.

Changzhou Runhua Electric Appliance Co., Ltd

Address: Jinsheng East Road, Jintan City, Jiangsu Province

website: www.runhuayiqi.com

Email: 394514722@qq.com

Tel: 0519-82305398 / 82301086 / 82321286

Fax: 0519-82306938

Welcome to the official website of Runhua Instruments. We are a professional manufacturer of laboratory instruments. Quality and reputation a…

The water bath constant temperature shaker is a biochemical instrument that combines a temperature controllable constant temperature water ba…

Series of biochemical incubators:Features of 150A biochemical incubator: the biochemical incubator has the function of cooling and heating tw…

High-precision stirring water bath produced by Runhua Instruments:1) The general water bath does not have the circulating stirring function. …

Maintenance and maintenance of electric mixer1. Correct use and attention to the maintenance of the instrument to keep it in good working con…

What work should be done in the use of digital display stainless steel electric heating plate? Digital display stainless steel electric h…